Strictly control the technical threshold of liquid-cooled connection to promote long-term operation

Date:2023-09-21 | Hits:2332

With the continuous growth of computing power, liquid cooling has become the first choice for efficient cooling in current data centers. In the liquid-cooled cabinet, the quick connector serves as the key bridge between the cold plate and Manifold, enabling quick disconnection of the liquid cooling circuit and providing indispensable support for long-term stable operation of the liquid cooling system, mainly for daily preventive maintenance, online hot swap in case of failure, and maintenance. And when the main component fails, it is easy to quickly use the remaining parts or redundant equipment to maintain the normal operation of the system.

However, a single fast connector in a liquid cooling system, which serves as a critical "node" throughout the data center network, is also a potential failure point, and a coolant leak triggered by connector failure can cause an entire server rack to fail. Therefore, the safety and reliability of the connector is crucial to the entire liquid cooling system.

In order to make the industry better understand the technical requirements of the liquid cooled connector, and then successfully select a safe and reliable fast connector in the design process of the liquid cooling system, industry experts in the previous experience sharing, focusing on the connector design, structure, quality and production process control and other aspects of the in-depth analysis, for the following technical requirements, be sure to strictly control:

Robust construction and design

The liquid-cooled connector is not a cheap "consumable", can not only consider the purchase price, but also should reasonably consider the total cost of the component in the entire life cycle, so you need to choose a material specifically for low-voltage applications and strong structure. Based on practical application experience, the metal joint assembly has a higher connection life (≥1000 times), high pressure resistance (16bar), and better mechanical adaptability (vibration/shock resistance) and climate adaptability (hot and cold shock/temperature and humidity cycle), which can meet various extreme conditions.

Dry disconnect capability

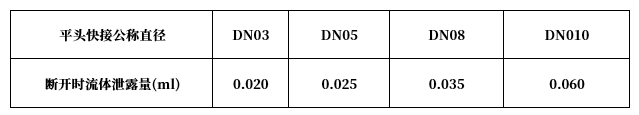

The quick connector must be equipped with a stop valve at both ends, which can automatically cut off the liquid cooling circuit when it is disconnected. At present, there are two common built-in valve structures: non-flat valve and flat valve. Non-flat valve (such as needle valve) quick joint will form a closed chamber when the spool is closed, and residual liquid will drip into the chamber after being completely disconnected, bringing safety risks to electronic components. In contrast, the flat valve quick connector adopts a drip-free design, which only forms a thin liquid film on the surface of the valve end when disconnected, so as to avoid the formation of droplet dripping, and is the ideal choice for liquid cooled quick connection. The following table is the latest CESA community standard, which provides a recommended value for the amount of liquid hanging when the flat head quick connection is disconnected, which can be used as a reference basis for selection:

Ease of operation

For liquid cooling systems, it is critical that the connector can easily disconnect the loop without causing any leaks, which requires it to be easy to operate in a small space, not only to simplify on-site maintenance, but also to ensure the safe availability of the product. Ergonomic design features such as color coding, docking orientation, ball locking devices, and moderate connections significantly reduce the work of operations personnel and make connections faster and more accurate, which are also important when selecting fast connections.

Production quality control

Every production process of fast connectors needs to be fully and strictly controlled. At the production stage, all parts are assembled and tested in a high-cleanliness workshop to minimize potential contamination risks, while each part is marked to ensure full life cycle traceability; In the quality control process, it is necessary to carry out separate quality control, such as air tightness testing, functional testing and customer customized testing; In the packaging process, from single joints to the outer packaging of batch products, adequate protection should be ensured to ensure the integrity and cleanliness of the joints.

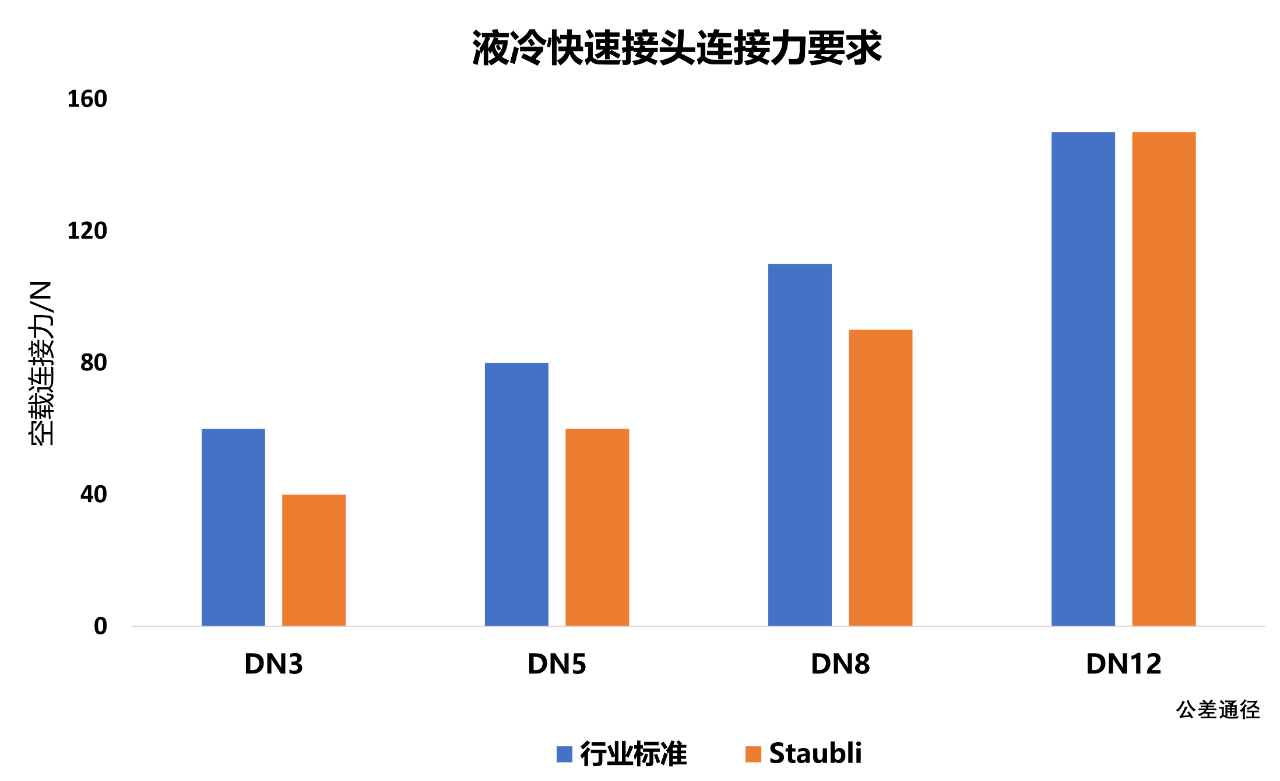

Only by strictly controlling the technical threshold of the liquid cooling connection and selecting the liquid cooling connector that meets the requirements can you ensure the long-term stable operation of the liquid cooling system and ensure the high availability of the data center. With 30 years of experience in the field of liquid-cooled connections, Staubli has always strictly followed and led the technical requirements, and has continuously designed and developed liquid-cooled connectors that are superior to industry standards. At present, a full range of family products can fully cover the full scenario application of data center liquid cooling systems such as server cabinets and high-performance computers, meeting different design requirements, and ensuring safety and reliability even under extreme and harsh working conditions.

At present, the green and low-carbon data center has become the focus of global attention, by taking the responsibility of protecting the safety and reliability of liquid cooled connection, continue to promote the innovation of liquid cooled fast connector technology and the establishment of standards, and will continue to provide global customers with excellent product quality, strict safety standards and efficient localized services covering the world. To make greater contributions to the construction and development of green data centers.