The technical principle, internal structure and development trend of the liquid-cooled cabinet

日期:2023年11月01日 | 浏览次数:2611

With the rapid development of information technology and cloud computing, server cabinets are more and more widely used in data centers. As a new cooling method, liquid cooling technology has the advantages of high energy efficiency, high density and low noise, so its application in the field of server cabinet has gradually attracted attention. This paper will introduce the technical principle, internal structure and development trend of the liquid-cooled cabinet in detail.

According to CCID Consulting, the market size of China's liquid cooled data center will grow from 26.09 billion yuan in 2019 to 128.32 billion yuan in 2025, and the industry growth rate will remain above 30%. The scale of China's liquid-cooled data center infrastructure market will increase from 6.47 billion yuan in 2019 to 24.53 billion yuan in 2025.

At the same time, according to the three major operators and representatives of the liquid cooling industry chain recently issued the "White Paper on liquid cooling Technology for Telecom Operators", proposing to carry out the scale application of liquid cooling technology in 2025, and 50% (that is, 50% for high-power cabinets) or more projects apply liquid cooling technology.

Combined with the relevant statistics of the Ministry of Industry and Information Technology: it is expected that the demand for new cabinets in China IDC in 2025 will reach 750,000 units per year, with an average annual increase of 380,000 units of cabinets above 10KW (KW), and the value of submerged liquid cooling single kW is about 12,000 yuan, and the average annual increase in the liquid cooling market size is about 45 billion yuan.

First, the technical principle of the liquid-cooled cabinet

Liquid cooling technology is a cooling method that uses liquid as a heat dissipation medium to take away the heat of the equipment in the server cabinet.

Specifically, the liquid cooling technology utilizes the high heat conductivity of the liquid to transport the liquid from the condenser to the various devices in the server cabinet by pumping, absorb the heat generated by the equipment, and then flow back to the condenser for cooling, recycling, and achieve efficient cooling effect.

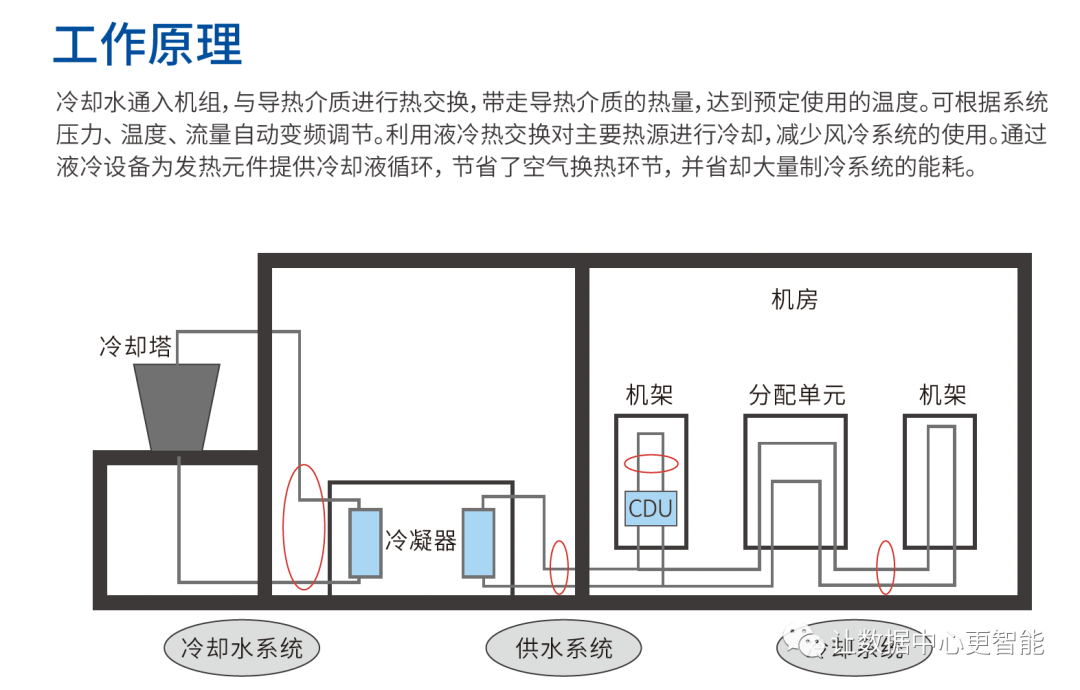

1.1 Technical principle diagram

Figure 1-1 Schematic diagram of the liquid cooling system

● Liquid supply system is responsible for providing cooling liquid, generally deionized water and glycol mixture.

The liquid circulation system consists of pumps, pipes and heat exchangers that carry the heat absorbed by the liquid from the server cabinet back to the cooling system for cooling treatment.

The cooling system is mainly composed of cooling tower, chilled water system and cooling system, which is responsible for transferring the heat in the liquid to the outside environment.

● The control system is mainly responsible for controlling liquid temperature, flow and other parameters to ensure the stable operation of the liquid cooling system.

● The monitoring system is responsible for real-time monitoring of the operating status of the liquid cooling system, timely detection and handling of faults. (The monitoring system is not listed in the figure)

Second, the internal structure of the liquid-cooled cabinet

The internal structure of the liquid-cooled cabinet mainly consists of the following parts:

● Server equipment area: The area where the server is placed, and the heat generated by the equipment is dissipated by the liquid cooling system.

● Liquid circulation pipeline: the liquid circulation channel in the liquid cooling system, including liquid inlet pipeline, liquid outlet pipeline and circulation pipeline.

● Condenser: The equipment that transfers the heat in the liquid to the external environment, usually using plate heat exchanger or shell and tube heat exchanger.

Cooling water tower: equipment that provides cooling water and transfers heat to the atmospheric environment.

● Pump: Equipment used to drive liquid circulation, usually using centrifugal pumps or screw pumps.

● Monitoring system: equipment for real-time monitoring and control of the operating status of the liquid cooling system, including temperature sensors, pressure sensors and liquid level sensors.

● Electrical control system: used to control the electrical components of the liquid cooling system, including control cabinets, power supplies, etc.

● Maintenance structure: including maintenance facilities such as cabinet doors, observation Windows and filters.

Third, the development trend of liquid-cooled cabinets

With the rapid development of cloud computing and data centers, the cooling problem of server cabinets has attracted more and more attention. As a new cooling method, liquid cooling technology has a broad application prospect in the field of server cabinets, and there will be the following development trends in the future:

1) More energy efficient

As the scale of data centers continues to expand, the energy requirements for cooling systems are becoming higher and higher. Therefore, the energy efficiency of liquid cooling technology is an important direction for future development. By optimizing the design of the liquid cooling system and selecting efficient pumps and heat exchangers, the energy efficiency of the liquid cooling system can be improved, thus reducing the energy consumption of the data center.

2) Lower noise

The traditional air cooling system produces large noise due to the rotation of the fan, which is unfavorable to the operating environment of the data center. The equipment such as pumps and fans of liquid cooling systems produce relatively little noise, which can better meet the needs of data centers for low-noise environments. In the future, the noise level of liquid cooling equipment can be reduced by further optimizing the design and technical parameters of the liquid cooling system.

3) More flexible and expandable

With the rapid development of cloud computing and virtualization technologies, the scale of data centers continues to expand, and the demand for the number and configuration of server cabinets is also increasing. Therefore, the design of liquid-cooled cabinets needs to be flexible and scalable to meet the requirements of data centers of different sizes and server cabinets of different configurations. Through the modular design method, the various components of the liquid cooling system can be standardized and universal design, which is convenient for later expansion and maintenance.

Technical advantages mainly have the following points:

1) In terms of computing power consumption

Full liquid-cooled cabinet can achieve high computing power density, a single cabinet supports up to 160 cpus, a cabinet top ten cabinets, and achieve high power supply density, can support a single cabinet of 100kW power density, compared to the traditional data center power density increased by more than 10 times, space utilization increased by 5-10 times, at the same time, the back door heat exchange force of 20kW, energy consumption is less than 2kW.

2) In terms of heat transfer efficiency

The natural liquid cooled back door is closer to the heat source than the air conditioning system, avoiding the local hot spot generated by some of the higher power consumption parts of the original air conditioning cooling heat, to achieve efficient heat exchange, and the energy efficiency ratio of more than 10 (COP refers to the conversion ratio between the cold amount generated in the refrigeration system and the energy consumed, the greater the energy efficiency ratio, the more energy saved).

3) In terms of safety and reliability

Relying on advanced pipeline welding technology, the full liquid-cooled cabinet system has strong pressure bearing capacity, which can bear 1.6MPa to ensure stable operation of the system; In addition, the four-fold anti-leakage design is adopted, and the leakage monitoring device is deployed on the surface of the cold plate nodes. Once the liquid leakage is detected, the system automatically stops, so as to protect the safety of the equipment. At the same time, the leakage monitoring is also deployed at the bottom of each cabinet, the natural liquid cooling back door, and the entire equipment room pipeline.

Fourth, the prospect and challenge of liquid cooling technology

As a new cooling method, liquid cooling technology has a broad application prospect in the field of server cabinet.

Several development routes of liquid cooling technology:

1) Cold plate liquid cooling refers to the non-contact liquid cooling technology that uses liquid as a heat transfer working medium to flow in the internal flow channel of the cold plate and cools the heat source through heat transfer. In a cold plate liquid cooling system, heating devices such as server chips do not directly contact the liquid, but are dissipated by cold plates mounted on electronic components that need to be cooled. Li Jinbo, deputy general manager of the product department of Tidal Information Data Center, pointed out that the cold plate liquid cooling uses the coolant flowing in the cold plate for non-contact heat dissipation, which changes the momentum of the existing server chip components and accessory parts, and is a liquid cooling cooling solution that is currently applied earlier and with higher technical maturity.

2) Submerged liquid cooling means that the server is completely immersed in the coolant, and the heat of all heating elements is directly transferred to the coolant, and then heat is dissipated through the circulation flow of the coolant or the phase transition of evaporation and condensation. Among them, the coolant circulation flow mode is single-phase immersion liquid cooling, and the coolant evaporation and condensation phase transition mode is phase immersion liquid cooling. The control of phase transition immersion liquid cooling is more complicated and requires higher requirements.

Submersible liquid cooling is relatively innovative, but the verification is insufficient. The coolant flow rate of unidirectional immersion liquid cooling will be very slow, and the pressure problem of gas and liquid will exist in phase change immersion liquid cooling, and the reliability of the technology still needs to be verified. In addition, the coolant used for submerged liquid cooling is not conductive, but it still requires continuous drying of the coolant.

3) Spray liquid cooling is the use of coolant directly spray chips and other heating units, through convection heat transfer for heat dissipation, generally do not need to make significant changes to the infrastructure of the data center.

Challenges of liquid cooling technology:

Innovation in the data center liquid cooling market is extremely active, and the discussion about the advantages and disadvantages of various liquid cooling technologies such as immersion, cold plate, and spray is one after another. Although there is a "route dispute", no matter what kind of technical route is chosen, the cost is still a roadblock in front of liquid cooling technology;

According to industry estimates, the initial construction cost of liquid-cooled data centers is about 10% higher than that of air-cooled data centers, and it takes 1.5 years to achieve the balance between total cost of ownership and return on investment.

Liquid cooling technology is very complex, involving the liquid cooling data center system architecture layer, liquid cooling components and interface layer, liquid cooling infrastructure layer (liquid cooling cabinets, components, heat exchange equipment, outdoor integrated cold source, etc.), liquid cooling monitoring system layer and other aspects, the industrial chain of enterprises have a variety of technical paths, product specifications vary greatly. It is difficult to standardize the adaptation and deployment of liquid cooling technology.

A realistic problem is that although liquid cooling technology was born earlier, it has been in the small-scale deployment stage, and many chain enterprises still rely on "small-scale trial production" to complete the delivery of products and services, and it is difficult to form a standardized and large-scale development trend.

Source: Make data centers smarter